Fitted Bookcases

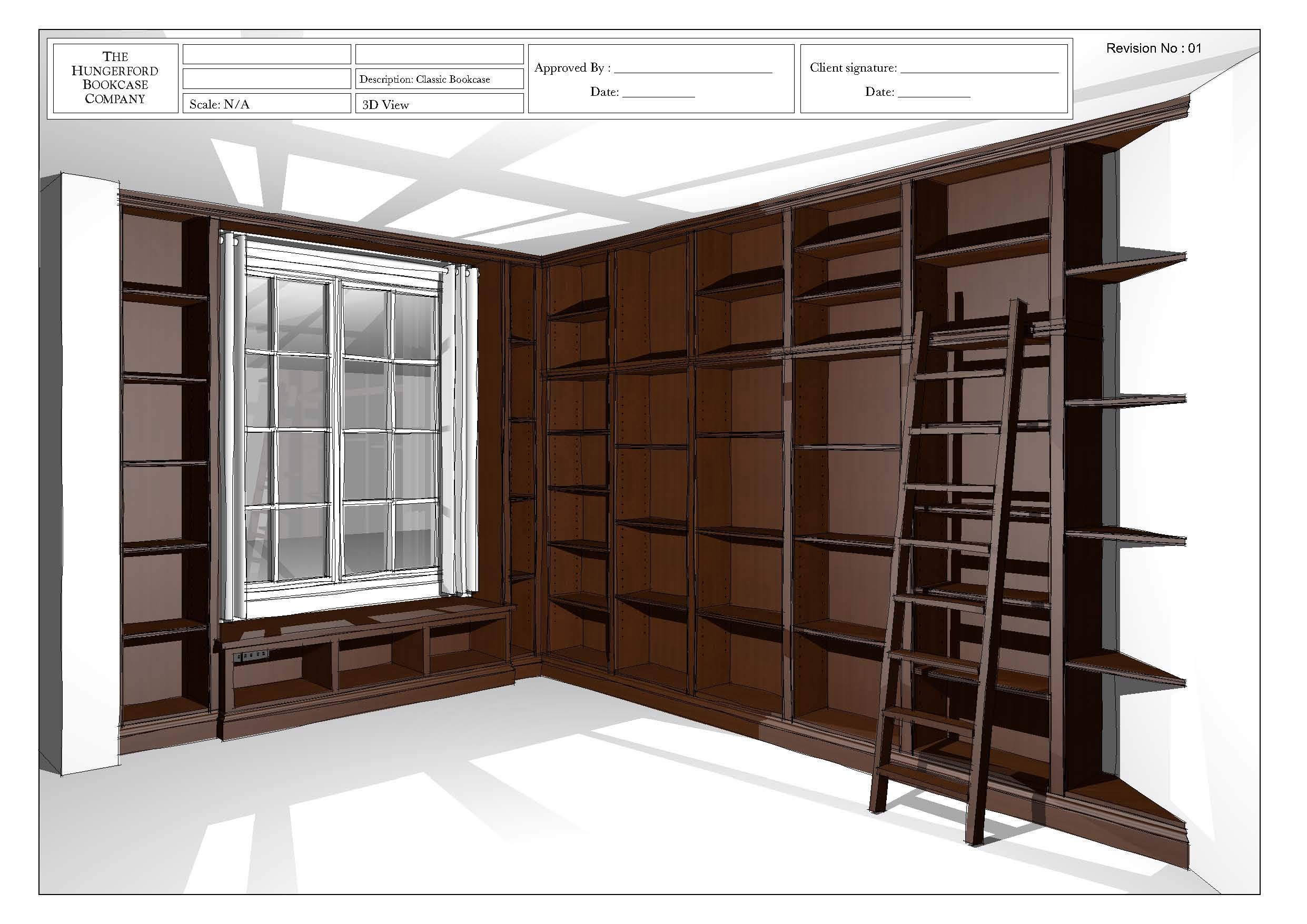

The only thing in common with each project is that each one is different!! Every project is unique whether it be size, colour, design……..each bookcase is made for the customers needs and the property in which it is going.

Our process is that once you have made contact expressing an interest in commissioning a piece of furniture. We will request from you some basic information regarding the space and project. This will include pictures, basic measurements of the room with positions of doors and windows and any other important features. We will also require any specific requirements that you may have.

With this information we will issue you with an initial quotation for the work breaking down the various options and elements including installation. If you then wish to take the project further we will require an initial design deposit of £750.

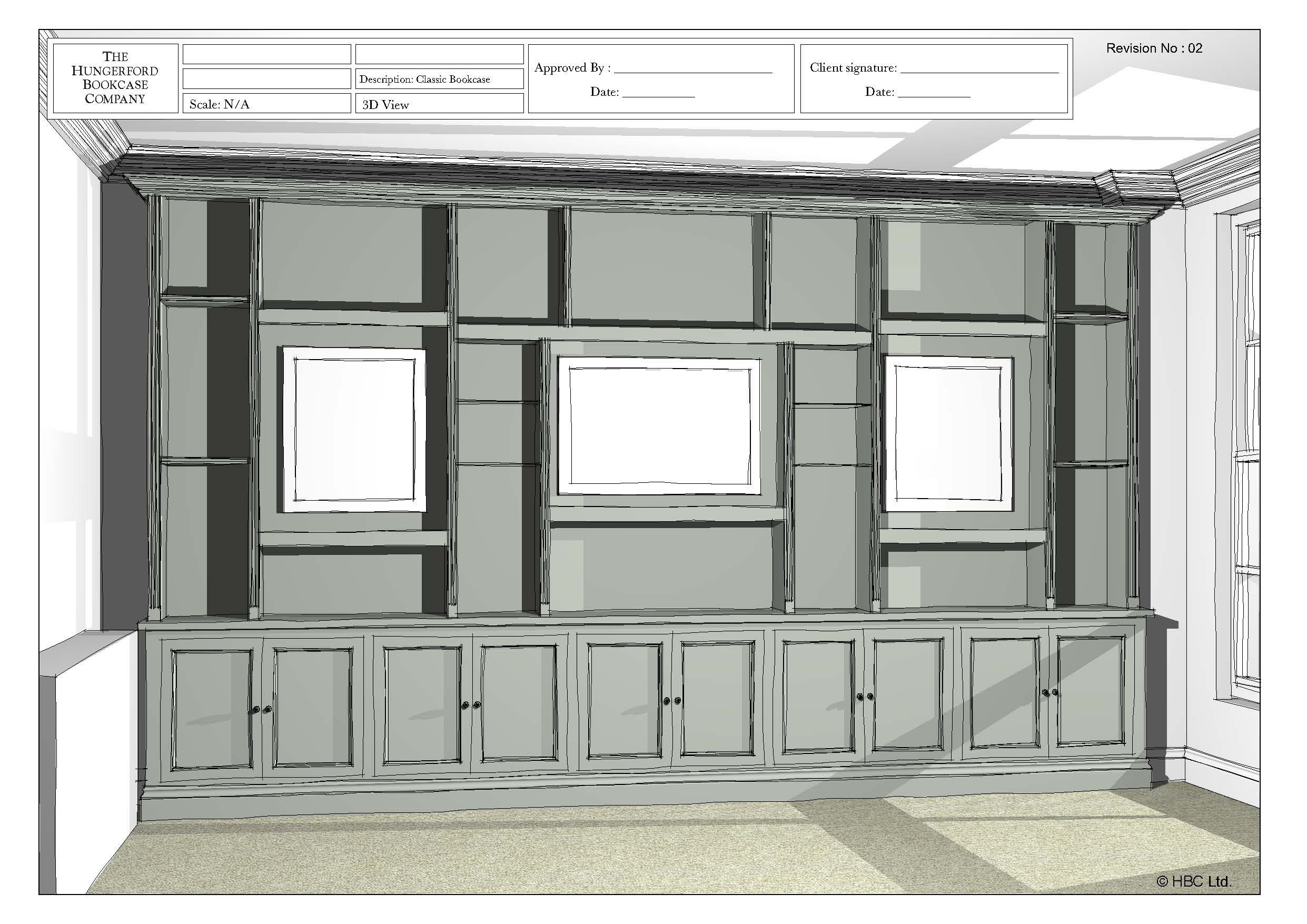

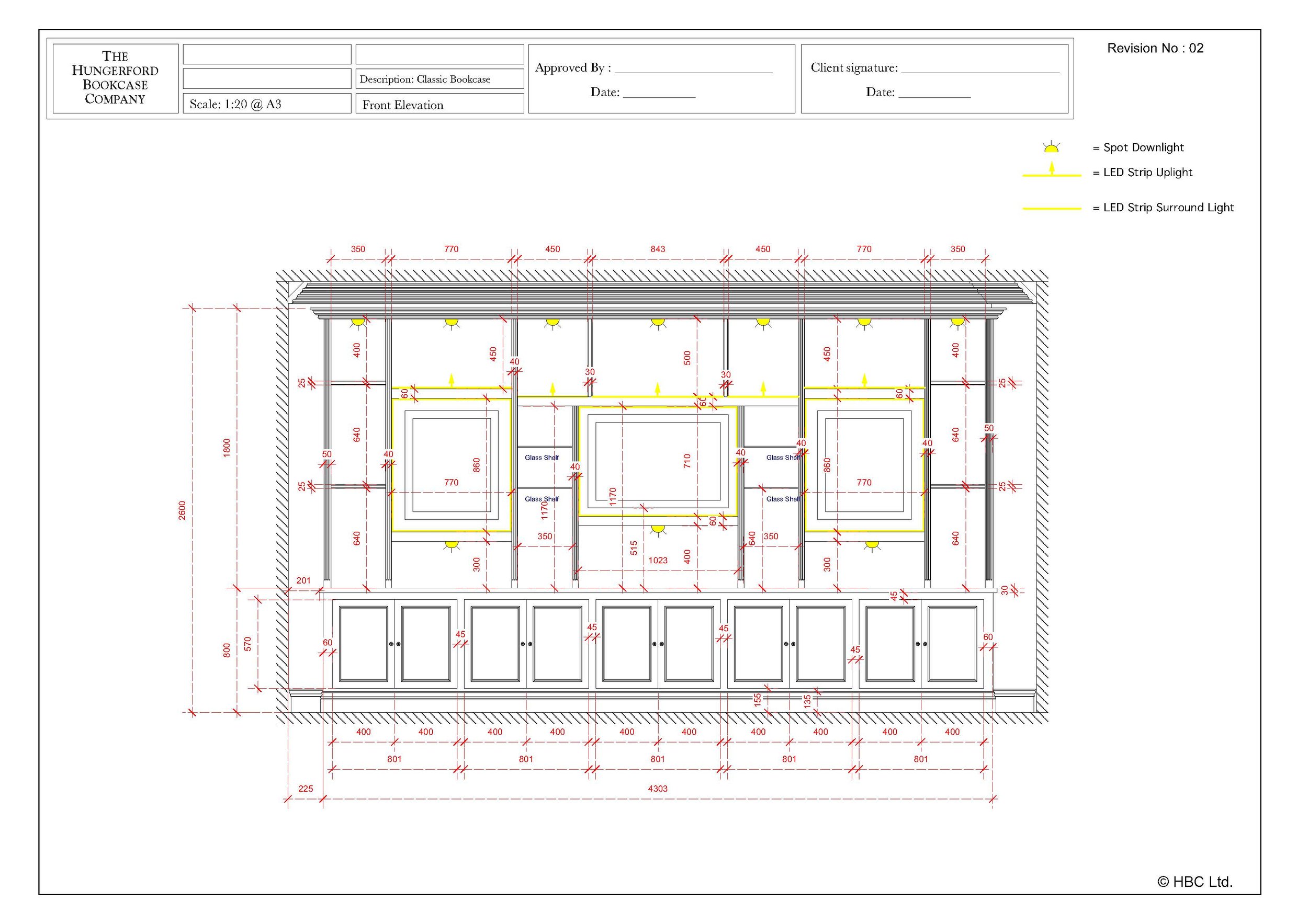

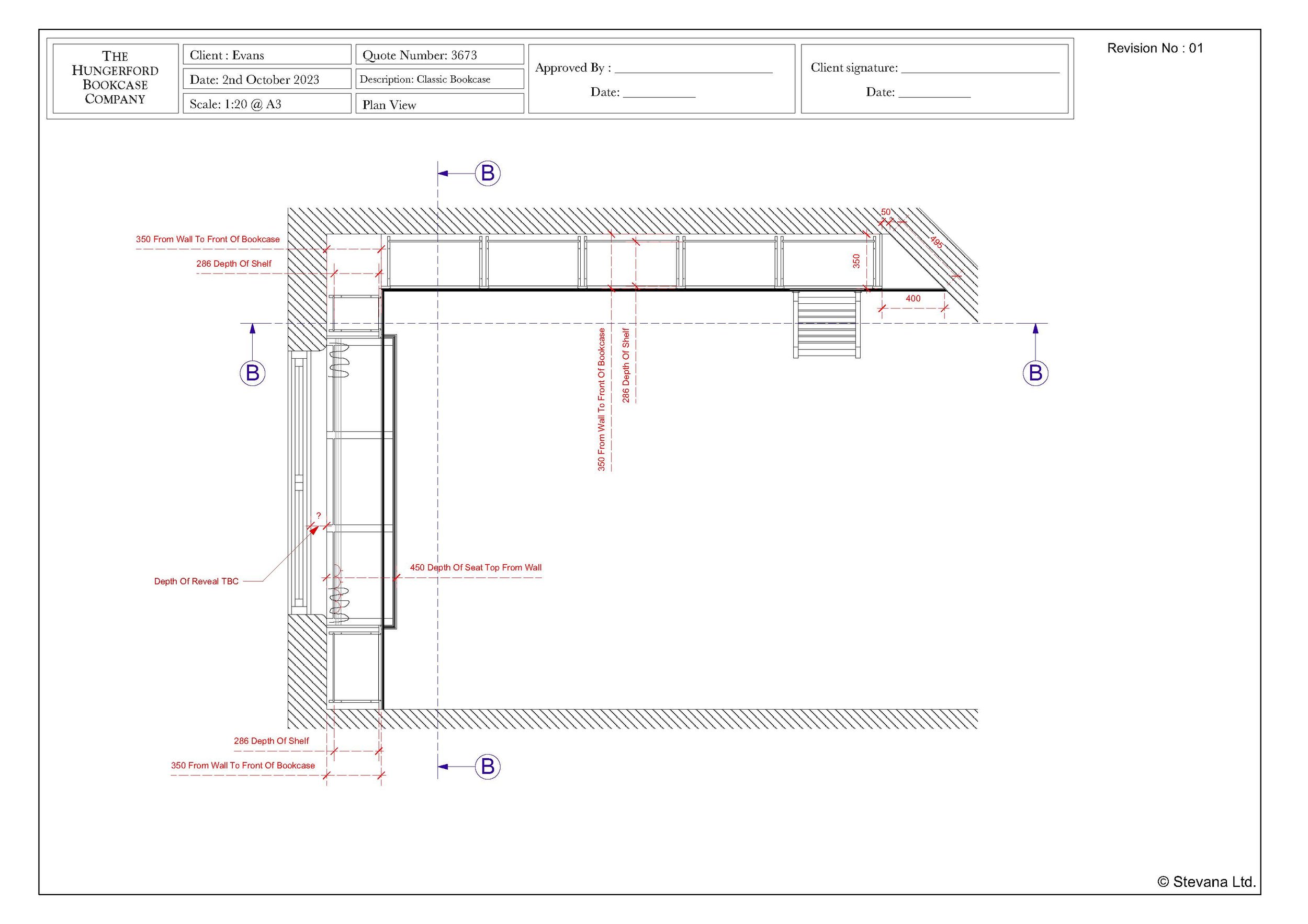

One of our cabinet makers/installers will then visit you in your home, conduct a full site survey of the space. This information will then be handed over to one of our technical design team. Detailed CAD 3D drawings will be created for you to approve and these drawings will be used to make your furniture. Final finish samples will be sent to you with hard copy drawings. Upon approval from yourself, production of your furniture will start. The furniture is made by hand by the maker that visited the property before being finished by our in house furniture finishing team. The maker will then deliver assemble and install the furniture in your home. The approximate time from approval of the drawings to install is approximately 6 weeks.

There is of course so much to think about when considering furniture for your home. One of the big questions customer ask themselves is how much should a project cost or……”what do I get for my hard earn £”!

Most furniture today is imported from half way across the world with limited sizes and design/finish options. There is also lots of ‘cheap’ furniture on offer which is designed to last a limited time. Websites use words to describe a finish whilst being vague and not really revealing what its made of or indeed how its made. This can make it very difficult to judge value for money and know what you are getting.

@HBC we like to be transparent about our processes and the materials we use. All of our furniture is ‘bespoke’ in that not only can we offer any size with limitless options, the materials and timbers used can be tailored to our customers requirements. Standard painted furniture is made using a combination of materials including solid maple wood, tulip wood, moisture resistant MDF and birch ply. Timber finished furniture is constructed with solids, solid lipping’s and real wood veneers bonded to stable furniture boards. Joints and construction methods are traditional using mortice and tenon frames, dovetailed drawers, panelled 5 piece doors. To keep it simple its furniture made for life!! It doesn’t just stop there as our finishes are durable yet mindful of the environment. All of our finishing products are water based which includes paints and lacquers. These can be either from our own fantastic range of colours or you can specify your own bespoke finishes.